The Advantages of A Digital Factory Amidst a Global Pandemic

The COVID-19 pandemic presented important challenges, affecting not only our private spheres, but also our working environments. It brought to light a missing test most companies in the manufacturing sector had been procrastinating about: digital transformation. However, in Whirlpool EMEA (Europe, Middle East, Africa), we can proudly say we were more than fit for the task, as we had already started implementing a number of innovative solutions and applications through our Digital Factories.

The concept of Digital Factory derives from other trendsetting initiatives, namely Smart Manufacturing and Industry 4.0, and it represents a clear and ambitious vision for the manufacturing of the future. It can be imagined as a place where all the resources involved—machines, robots, equipment, people, organization, processes and information systems—are supported by computing power, which is capable of interconnecting all these elements in the following way:

- Sensing what is happening,

- Connecting and analysing all the data,

- Sharing this data among all of the resources,

- Providing indications and predictions of what is going to happen,

- Actively supporting the purposeful human decision process, and, in some cases,

- Activating automatic actions.

In the image above, we can see how a Digital Factory comes as a natural evolution on the Industry 4.0 roadmap. At each stage, it becomes necessary to have the right combination of technology and skills, which, due to their ever-evolving nature, need to be constantly checked upon and improved. Just like our digital applications. For this reason, we first scope out the best solutions, then we test them properly, and, only once they have a robust and solid foundation, we apply them to our production.

However, we do not do this all by ourselves. We rely on a network of highly capable external partners. Back in 2010, we started a series of public research and innovation programs, leveraging a variety of structured and continued collaborations with important universities, research institutes and tech companies, including Horizon 2020 and the European Institute of Technology and Innovation (EIT). To date, at Whirlpool EMEA, we have carried out more than 15 research and innovation projects in some of the latest development areas, allowing us to tackle all sorts of future needs, such as the following:

- People and robot sustainable work: In a Digital Factory, people and machines have to work in constant cooperation, so it is necessary to design hybrid workstations and improve the robots’ sensing capability, for them to identify their human counterparts and environment, and better adapt their behaviour consequently.

- Zero-defect and circular economy: AI’s advanced sensing will be a crucial tool for us to achieve our zero-defect standards, improving the way we measure and test our products and processes.

- Digitalized value network: It is fundamental to be knowledgeable about the vast amounts of data generated by a factory’s internal processes; using this data allows us to understand our current status, improving the decision making process both in terms of speed and of effectiveness.

The recent COVID-19 emergency was the perfect occasion to prove how a Digital Factory can outperform a traditional one, taking advantage of remote working, augmented, digital and virtual reality, and collaborative workstations to help tackle the before-mentioned needs. Here are some examples:

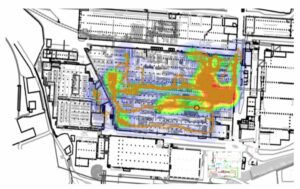

By using the Google Cloud platform, we enabled workers to perform Remote Monitoring, allowing them to have access to all factory operations and Key Performances Indicators in real time and from everywhere, ensuring optimal management and a fast and effective decision making process.

By using the Google Cloud platform, we enabled workers to perform Remote Monitoring, allowing them to have access to all factory operations and Key Performances Indicators in real time and from everywhere, ensuring optimal management and a fast and effective decision making process.

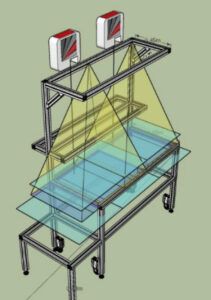

Providing on-site training while respecting social distance rules was one of our greatest rewards. Thanks to our Augmented Reality enabled training stations, we could substitute the human trainer with an intelligent system, which could project virtual images onto real objects, allowing workers to learn to assemble complex parts while maintaining a safe distance.

Providing on-site training while respecting social distance rules was one of our greatest rewards. Thanks to our Augmented Reality enabled training stations, we could substitute the human trainer with an intelligent system, which could project virtual images onto real objects, allowing workers to learn to assemble complex parts while maintaining a safe distance.

In just a few days, and while working from home, our engineers were able to use a variety of Digital and Virtual Reality tools to redesign new workstations, working cycles and line layouts, respecting all of the new COVID-19 countermeasures.

In just a few days, and while working from home, our engineers were able to use a variety of Digital and Virtual Reality tools to redesign new workstations, working cycles and line layouts, respecting all of the new COVID-19 countermeasures.

Automated and Collaborative Workstations and Robotized Material Delivery guaranteed business continuity in places where human operations would have been very difficult and unsafe. Mobile Industrial Robots ensured automatic material delivery in perfect harmony with human workers and in a safe manner.

Automated and Collaborative Workstations and Robotized Material Delivery guaranteed business continuity in places where human operations would have been very difficult and unsafe. Mobile Industrial Robots ensured automatic material delivery in perfect harmony with human workers and in a safe manner.

Digital Factory has proven to be the best-in-class solution for the future of our industry, leveraging remote working, agile manufacturing and plenty of innovative applications that ensure our utmost priority: our people’s safety. In these ever-evolving times, we pledge to continue to innovate and invest in state-of-the-art solutions to find the right balance between human and machine interaction, and guarantee our business continuity.

– Luigi La Morgia, VP Integrated Supply Chain, EMEA