An Integrated

Effort Around

the World

As the outbreak of COVID-19 continues to impact us around the world, there is no doubt that our everyday lives have fundamentally changed. Still, despite how different today feels, a constant remains—how we all care for each other, our families and our communities. All of us at Whirlpool Corporation understand how incredibly important this is, and as families were staying at home, they depended more and more on our brands and products to help them take care of their loved ones.

At Whirlpool Corporation, our vision is to be the best kitchen and laundry company, in constant pursuit of improving life at home. Beginning with the onset of the pandemic, it became more critical than ever to live by that vision each and every day for the benefit of our employees, consumers and communities. We understand that we play an essential role in the efforts to contain COVID-19 and do not take that role lightly. Our manufacturing plants have remained open and working to produce the refrigerators, dishwashers, and cooking and laundry appliances that are needed to keep people safe at home.

Employees

The health and safety of our employees around the world remains our top priority—we know that we couldn’t do any of this without their tireless commitment. We have implemented the proper safeguards in our plants in line with the guidelines provided by the CDC and other health organizations around the world, and continuously monitor and adjust on a daily basis. This includes heightened cleaning protocols, increased distances on our production lines, making the decision to slow production lines down or reduce lines as needed, and emphasizing proper hygiene in the plants, including use of frequent hand-washing while ensuring our employees have proper sanitization equipment.

Actions at Our Facilities

Cleaning Protocols and Social Distancing

- Heightened cleaning protocols at each plant, including the frequency of deep cleanings and using a third-party deep clean/disinfection.

- Increased distance on our production lines to facilitate social distancing as recommended by the WHO and the CDC. We slowed down the production lines and reduced lines as needed to ensure safe distancing between employees.

- Implemented food safety precautions in all our cafeterias and staggered break times to increase social distance.

- Emphasized proper hygiene in the plants, including use of frequent hand-washing, and ensure our employees have proper sanitization equipment.

Employee Self-Monitoring/Reporting

- Implemented temperature screening protocols for all our employees at our manufacturing facilities.

- Daily communication to all on-site employees to monitor their health (temperature and symptoms of illness) and a reminder to not come into work if they exhibit symptoms or have been exposed.

- Employees exposed to, or exhibiting symptoms of COVID-19 are required to self-report for further support and to start a mandatory quarantine.

Remote Work

- Employees required to work from home, if possible.

- Returning to the office environment will be a phased approach determined by local, state and federal guidelines, local health data and facility readiness.

Travel & Visitors

- Implemented a robust travel policy. All travel restricted to essential-business only, with leader approval.

- All employees who have traveled to high-risk locations, or have been exposed to others who have traveled to high-risk locations are required to complete a self-quarantine before returning to a Whirlpool facility.

- On-site visitors are restricted to business-essential only with leader approval. All visitors subject to self-monitoring/reporting policies.

Consumers

As the world continues to battle COVID-19, our consumers need our trusted appliances to take care of their families during this turbulent time. They are depending on our products—now more than ever—to clean, cook and provide proper food and medicine storage. The health and safety of our service providers and consumers is a top priority. With 78,000 employees globally, we have proudly continued to support our consumers throughout the pandemic through a variety of ways including:

- Continued to carry out service calls for repairs using approved safety protocols.

- Directed all employees and suppliers—including delivery drivers and engineers—to follow CDC guidelines on how to keep themselves and others safe.

- Implemented precautions such as contactless delivery, drop-off only delivery and verbal signatures upon delivery.

Community

With many families and households facing challenges, Whirlpool Corporation is committed to doing our part to help those affected in our communities. We have taken a number of steps in 2020 to help communities, including providing financial support and donating medical supplies and appliances to hospitals across the world. We also supported several local organizations providing vital services to the most vulnerable in society, such as food banks, shelters and school meal programs.

The following are examples of what we have done to help our communities during the pandemic. For more information, please visit our COVID-19 response to employees, consumers and community.

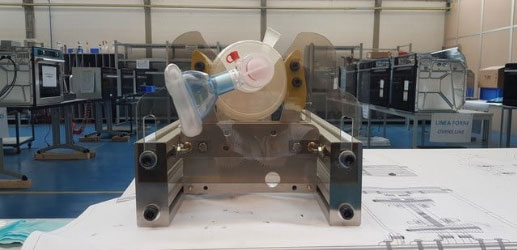

PAPR: Whirlpool Corporation, Dow Inc. and Reynolds Consumer Products Inc. collaborated to provide much-needed respirators to health care workers. Together, we designed and built a protective piece of headgear and respirator system, critical in helping ensure the safety and comfort of front-line workers who are often in direct contact with COVID-19 patients. The collaboration came about after the local hospital near our headquarters in Benton Harbor, Michigan said it was using its supply of N95 masks and respirators at a rate 10 times higher than normal. Our engineers and designers went to work to find a solution and designed the Powered, Air-purifying Respirator, or PAPR, a PPE device that takes the place of a traditional medical mask and visor and features a replaceable polyethylene hood. The clear hoods are both flexible and comfortable and can quickly be replaced between patients.

Our fully virtual team was able to go from paper to approved product in just seven weeks. Through this unique relationship and a huge amount of effort by a very talented group of people, we manufactured and donated respirators to help our front-line health care providers during the pandemic. Whirlpool Corporation designed, manufactured and assembled the headset. Dow provided the polyethylene resin for the hoods, and Reynolds Consumer Products designed and produced the disposable hood. We donated thousands of these to hospitals around the world, including Italy, Mexico and Brazil, and sold additional quantities globally at reduced cost to health care providers.

Mechanical Ventilators: Whirlpool Corporation engineers based in Cassinetta di Biandronno, Italy developed a mechanical ventilator, Breath4U, and a PPE face shield. To produce the Breath4U mechanical ventilator, our EMEA teams worked in partnership with Politecnico di Milano and numerous doctors working across hospitals in Italy. After recognizing a continued shortage of ventilators in hospitals and the associated cost and long production chain of traditional ventilators, the team modified their design to be able to produce more devices and make them affordable.

The mechanical ventilator the team designed is a control logic, low-cost device that assists the breathing of patients in pre-ICU situations—such as triage, ambulances and emergency departments, where ventilators are not immediately available. The mechanism of Breath4U is based on an Ambu ball that automatically receives a controlled amount of pressure applied by two grippers, and counts with a graphic interface which allows doctors and health care staff to easily set the breathing parameters. It was based on an MIT open-source project, where five prototypes were made to later be tested in Politecnico’s TechRes (Laboratory of Respiration Technologies) and the partner hospitals.

The final prototype was built with components easily sourced on the market, even in health care emergency conditions. The project underwent an initial IMQ (a product standards certification body in Italy) certification phase to test its electrical safety and is now available on an open-source basis to anyone needing to produce it rapidly.

Face Shields: To help produce effective and low-cost PPE face shields, Whirlpool Corporation designers started out with a number of open-source projects. As many of those projects involved the use of 3D printers, we adapted existing 3D printers available in Cassinetta, Italy R&D laboratories to start making samples. Additionally, to further increase face shield production capacity, our engineers assembled a new, bigger 3D printer from scratch. The face shield design was gradually improved, also in collaboration with Politecnico di Milano, up to the moment when we obtained the certification. This close collaboration allowed us to quickly reach an optimum compromise between design, materials and overall performance of the face shields. Moreover, given the success of the initiative and high demand, in just two weeks, our teams made a plastic injection mold with a production capacity of around 2,000 pieces a day, significantly expanding production volume.

Whirlpool Corporation also produced and donated approximately 16,000 face shields in Brazil, in a joint effort with a technology center. Our engineers designed a prototype and adapted a production line in our Joinville plant to cut and assemble the face shields that were donated to organizations in the cities around our sites.

In every country where we do business, our company and employees rose to the challenge of COVID-19, working closely with local organizations, health care providers and governments to provide the support necessary for the medical and safety front-line workers as well as the overall community.

- Donated appliances to local hospitals, shelters and community organizations.

(Southwest Michigan)

Soon after the COVID-19 pandemic hit, we began working to obtain several shipments of medical supplies for donation to Spectrum Health Lakeland, a health system near our Global Headquarters. We were able to procure more than nine shipments with tens of thousands of medical masks, gloves, thermometers, and hospital gowns to help front-line workers. Additionally, hundreds of appliances were donated to assist local hospitals, governments and supporting organizations around the world.

- Delivered PPE for health personnel and refrigerators and cooling equipment for medicine preservation in San Jose Hospital and in hospitals and shelters for abandoned children in other cities.

- Provided appliances to the Casa Paterna adoption agency.

- Donated masks for merchants in the Morelos Market.

- Manufactured face masks at the Horizon Apodaca Campus plant and delivered to 11 government facilities in Apodaca.

- Produced disposable face masks in our Celaya plant for medical personnel.

Donated refrigerators and washing machines to CONAPAM, National Council of the Older Adult.

Assisted the Colombian Red Cross and the Police Team, Bucaramanga.

Donated laundry and refrigeration appliances for a new health center.

- Launched Health Crisis Committee to support internal and external actions and government relations.

- Launched Employee Assistance Program (EAP) to support employees.

- Provided access to an app that provides online medical assistance to employees and relatives.

- Initiated #SeamosUno to donate 1 million boxes of food.

- Donated five washing machines to public hospitals.

- Donated 620 appliances to COVID-19 field hospitals.

- Manufactured approximately 16,000 face shields and 14,600 reusable masks.

- Donated more than 200,000 surgical masks and 150 PAPR devices.

- Helped repair ventilators and donated 5,092 food kits.

Donated products to A CASA (Centro de Apoio ao Sem Abrigo) and to INEM (Instituto Nacional de Emergência Médica).

Donated microwaves and refrigerators to Institut Català de la Salut.

Donated microwaves and refrigerators to Samusocial and #protegetonsoignant associations.

Donated appliances to a number of National Health Services hospitals and charities.

Donated washing machines and microwaves to COVID-19 shelters in Stuttgart.

Donated appliances to health facilities and fire brigades.

Donated refrigerators to two hospitals.

Donated washers and dryers to Thomayer Hospital.

Provided funding and support to the cities and regions in Italy where Whirlpool Corporation has a significant presence.

- €300,000 donation to support a variety of activities, ranging from research to the purchase of vital medical equipment for local hospitals.

- €60,000 raised by Whirlpool Corporation employees.

Provided medical kits and equipment.

- Donated high-end laundry products to four hospitals in Anhui Province.

- Collaborated with the China Organ Transplant Development Foundation to donate iced beverages and 10 refrigerators to the Centers for Disease Control and Prevention in Haidian and Yanqing District, as well as the Beijing Friendship Hospital.

Donated appliances to support local health facilities.