Operational Excellence

We are focused on continuous improvement throughout our operations and services. At our manufacturing facilities, we have worked to reduce water and energy use, greenhouse gas emissions and raw material waste.

Fourteen of our U.S. based facilities are certified for Leadership in Energy and Environmental Design (LEED). Our Cleveland, Tennessee plant received an award from the Kentucky-Tennessee Water Environment Association for outstanding performance in the pre-treatment of industrial wastewater. The Cleveland plant’s sustainable design also earned gold LEED certification.

GRI G4 EN31

-

- US$ Millions

-

- 2011

- 31.8

-

- 2012

- 29.5

-

- 2013

- 27.0

-

- 2014

- 30.5

-

- 2015

- 34.9

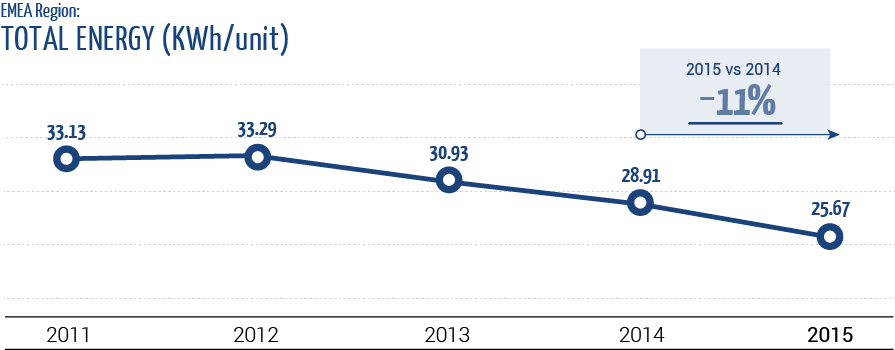

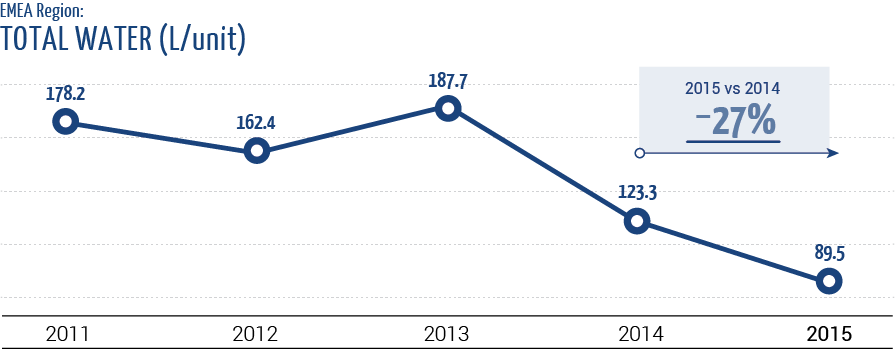

Global Facility Sustainability Program — Through partnerships with the U.S. Department of Energy’s Better Buildings Program and Better Plants Challenge, we initiated a program to provide a global dashboard feed from each of our plants and facilities to promote energy and water efficiency, waste minimization and benchmarking, allowing for cross-functional global collaboration and best practice sharing. This initiative is ongoing in our North America Region facilities, and connected with our global goal of lowering our energy intensity by 15% in 2020, considering 2014 as the baseline year.

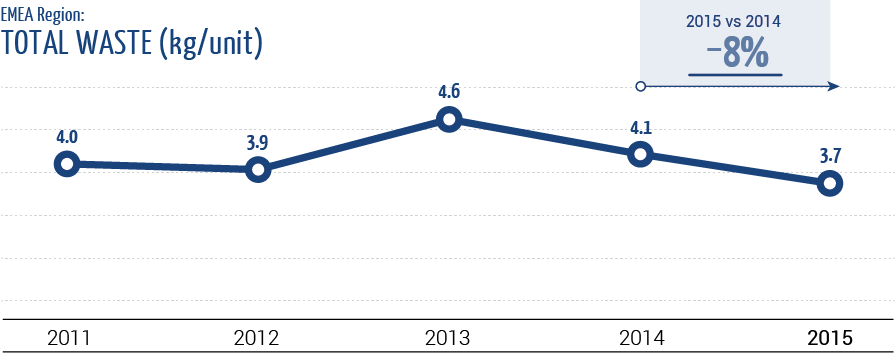

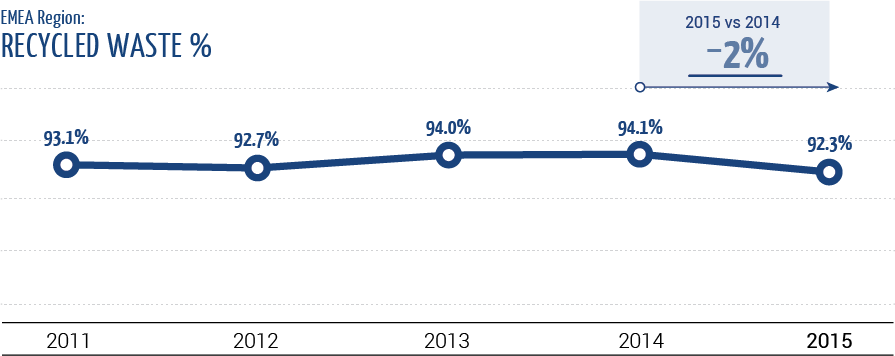

Another important goal we are working toward is the implementation of the zero landfill waste from manufacturing by 2022. We are very proud to say, four of our manufacturing facilities in Latin America have already achieved Zero Waste to Landfill.

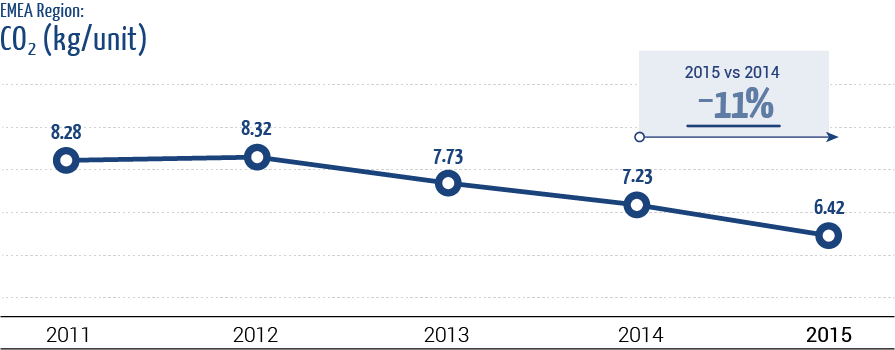

The Europe, Middle East and Africa region (EMEA) has a Management System for Energy, Environment, Health and Safety (EEHS) that covers 43 sites and has been certified by a third party through a multi-site accreditation according to the ISO 14001:2004, OHSAS 18001:2007 and ISO 50001:2011 standards.

In Whirlpool EMEA, environmental protection and energy management are a priority and for this reason managed through a specific Company organization devoted to Energy, Environment, Health and Safety (EEHS) issues.

Company EEHS managers are responsible for overseeing facility energy and environmental activities and direct capital investments dedicated to specific action plans. Moreover, they are in charge of monitoring national and local legislation, as well as rules and regulations related to the environment. They ensure that senior management and plant environmental professionals understand the potential impact of new or revised policies on their operations, and also conduct compliance audits. Meetings are held regularly to coordinate regional activities. This enables EEHS managers to discuss results, share best practices, and carry out benchmark comparisons against main competitors in key areas, in order to define new actions. Where laws and regulations are less restrictive, we have established and are following our own standards, consistent with our commitment to environmental responsibility.

The energy and environmental plan sets both annual and long-term targets for each site relative to the principal areas of environmental focus: atmospheric emissions, water and waste. This plan is then monitored on a monthly basis to ensure that:

- plants operate within Company standards

- new courses of action are planned when required

- programs and interventions are realigned

- new and more challenging targets are set

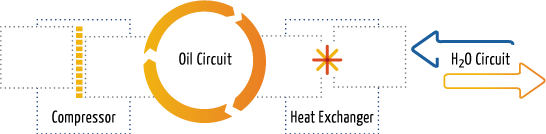

Generating ideas and sharing best practices on energy efficiency and environmental protection is a key objective of the EEHS EMEA team. In 2015 specific initiatives have been carried out: the launch of a website dedicated to internal best practices sharing and management where approximately 110 best practices were collected, which gave birth to approximately 90 ideas with a potential saving of approximately one million euros.